inspections

#Expert Control#

According to the regulations on work execution Chapter 13, various types of work equipment must undergo an annual inspection to ensure it is safe to use.

With DigiQuip, Equipment owners get a simple and efficient way to conduct and manage expert inspections, ensuring their equipment are safe to use and comply with current legal requirements.

- Safety: The purpose of expert inspections is to ensure that machines and equipment are safe to use. Identifying and correcting faults or deficiencies can prevent accidents and contribute to a safer work environment.

- Regulatory compliance: The Norwegian Labour Inspection Authority requires certain types of work equipment to undergo expert inspections. DigiQuip helps ensure all regulations are met, and that documentation is easily accessible for inspections by authorities.

- Efficiency: DigiQuip simplifies the process of conducting inspections, recording deviations, and planning future inspections, saving time and resources.

Conduct an expert inspection:

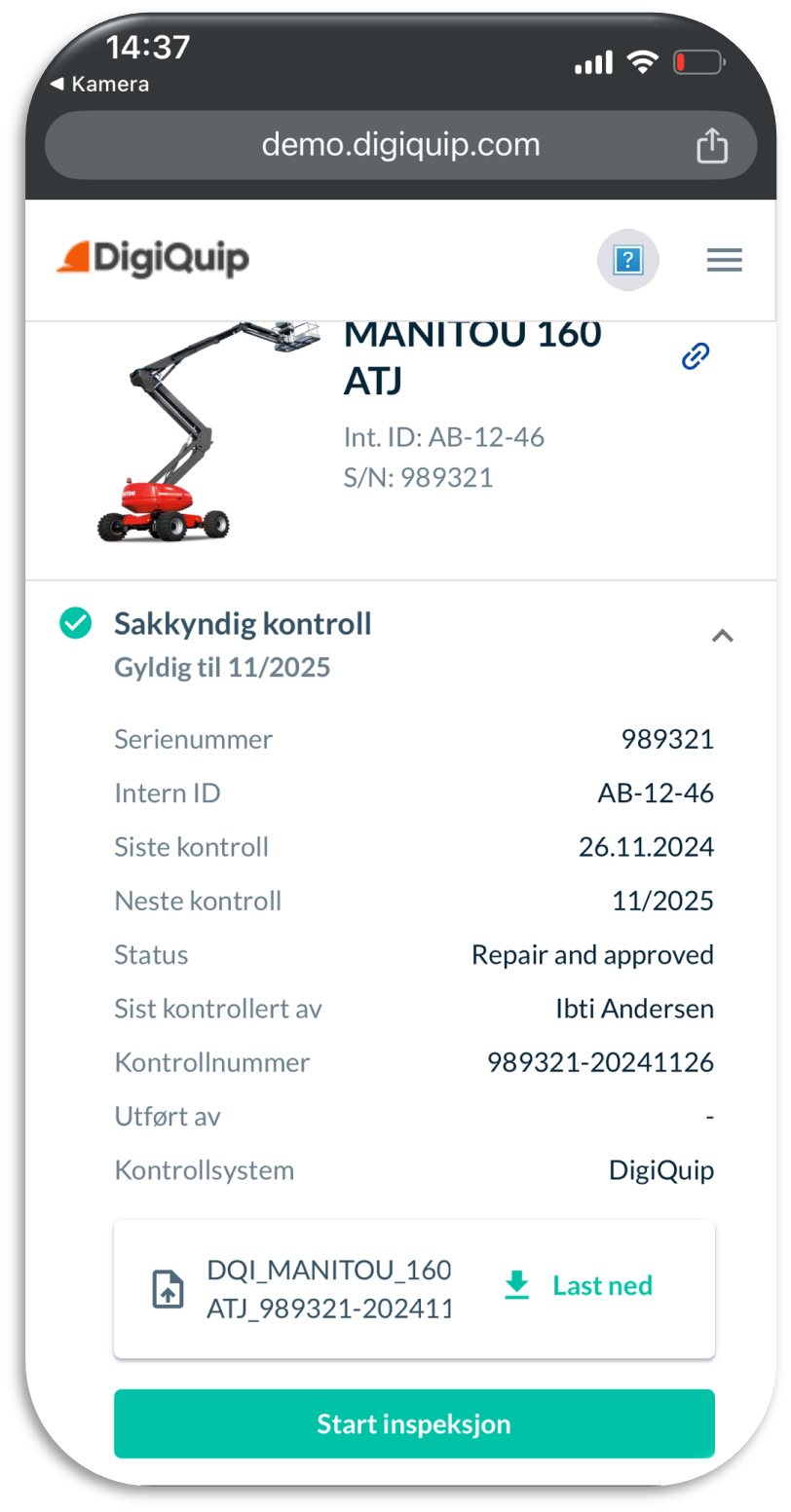

- To start an inspection, scan the QR code on the equipment.

- Select "Start Inspection".

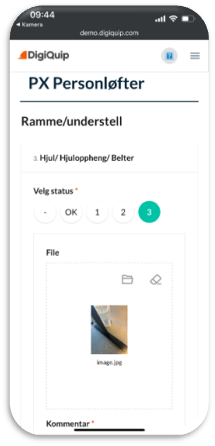

- Add If deviations and add comments

- Ensure that the "Last Inspection" and "Next Inspection" dates are correct.

- Add the houre counter (Mandatory).

- Select Use recommended (YES/NO). Note! Use recommended is set to (NO) by default.

- Complete the inspection.

Start post-inspection:

If deviations were recorded during the inspection, you can conduct a follow-up inspection on the same inspection.

- Scan the QR code on the equipment.

- The button that previously said "Start Inspection" will now change to "Start Follow-Up Inspection".*

- The follow-up inspection button is available for 8 months from the last inspection.

- You can add new photos.

- You can add comments. Note! Do not delete previous photos and comments.

Manage and plan equipment inspections

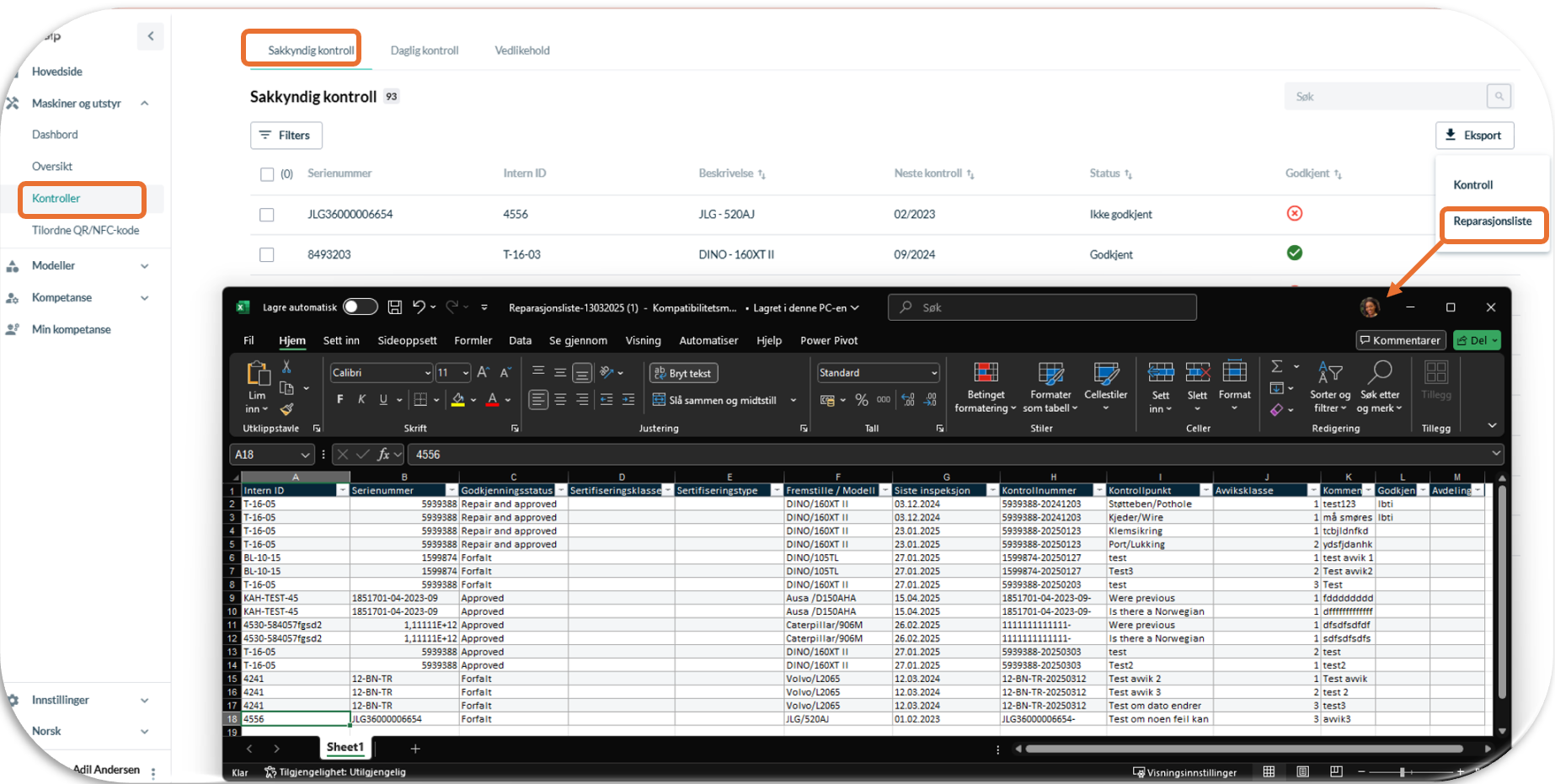

- Get a complete overview of all registered equipment with expert inspections on the inspection page.

- Filter by date (e.g., upcoming inspections) and view due dates.

- Click on the equipment to access the expert inspection tab.

- Export to Excel for sorting, department distribution, inspectors, or audit reporting.

- Export a list of equipment with deviations. This list updates when deviations are corrected.

FAQ

Here are some answers to frequently asked questions. Contact us if you don't find the answer you're looking for!

I scanned the QR code but don't see the "Start Inspection" button. Why?

Can I edit a completed inspection if I forgot to change the date/recommended use?

Can I start an inspection and save it to continue later?

Why can't I link a checklist to a model?

How do I change a checklist linked to a model?

Can I edit a completed inspection if I forgot to change the date/recommended use?

In DigiQuip, Equipemnt owners have control over expert inspections, and we are integrated with both the Machine Register (M-reg.) and BRAREG.

To retrieve inspection data from M-reg., contact the Central Register at [email protected] to obtain API details. These details can be entered directly under Settings > General > Integrations or sent to us via email.

We also offer customized integrations upon agreement.

For further details or questions, contact your representative or book a meeting with our team, book a meeting.